Fully integrated servo motors up to 1kW. SmartMotors reduce installation space, complexity and development time of your machine.

Home » Suppliers » Moog Animatics

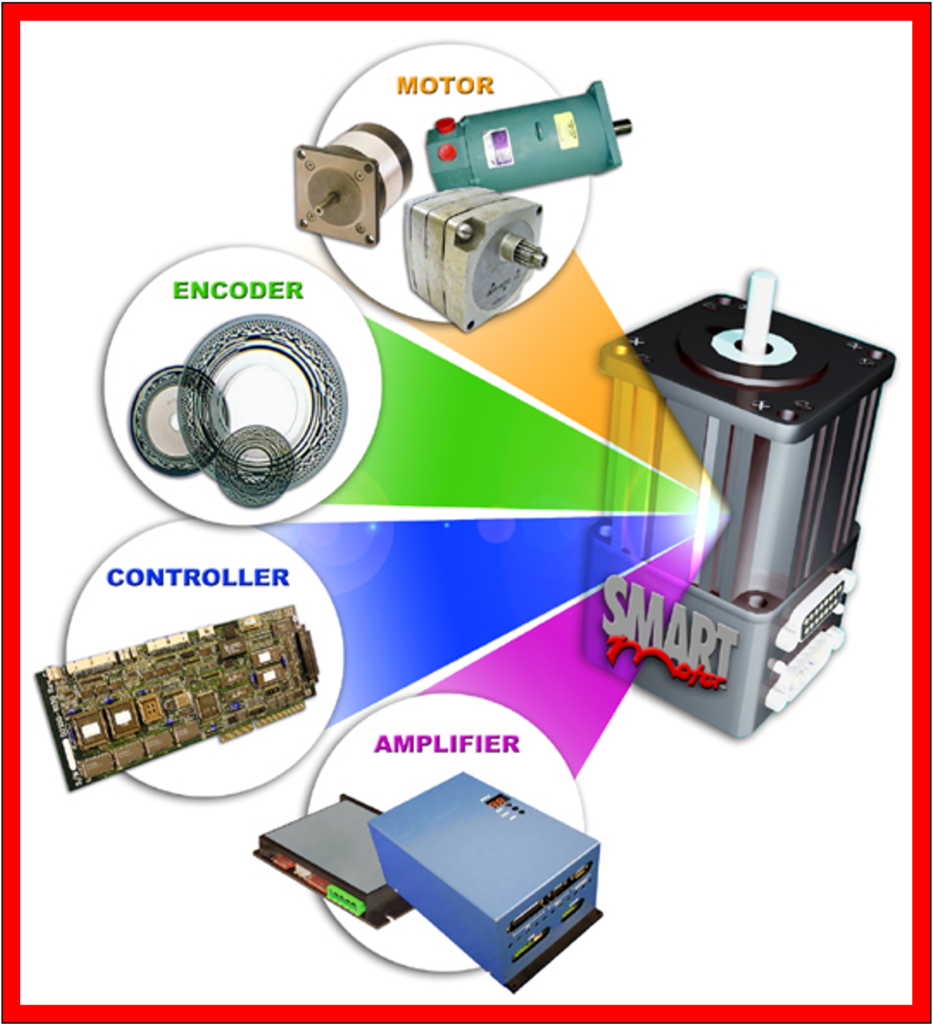

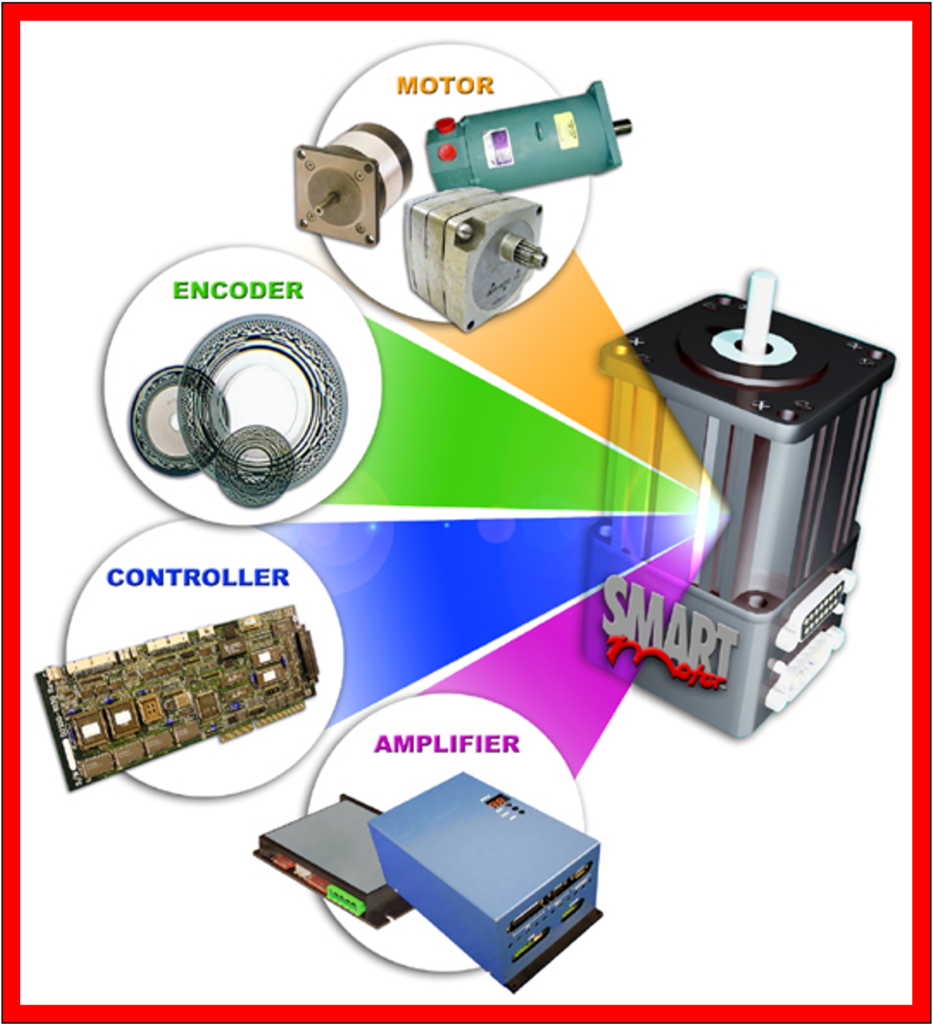

The Class 5 SmartMotor™ is a highly programmable, fully integrated servo motor system that incorporates a motor, an encoder, an amplifier, a controller, serial communication, and IOs in one compact package. All D-style SmartMotor™ have a primary RS-232 communications port, …

Animatics – Class 5 M Style The Class 5 SmartMotor™ is a highly programmable, fully integrated servo motor system that incorporates a motor, an encoder, an amplifier, a controller, serial communication, and IOs in one compact package. They also feature …

The Animatics Class 6 D-Style SmartMotors deliver high performance and precision in a compact package. These motors integrate a motor, amplifier, controller, and multi-turn absolute encoder into a single unit. This integration provides a seamless solution for various industrial applications. With a …

Animatics – Class 6 M Style The Class 6 M-Style SmartMotor lineup includes EtherCAT® (EEC option), PROFINET® (EPN option), and EtherNet/IP™ (EIP option) versions. These motors are designed for maximum performance and connectivity. They incorporate a high-end, high-speed processor for …

A SmartMotor is an integrated servo motor, where the drive, controls, IO, program and encoder are built into the motor.

What makes the Moog Animatics SmartMotor™ by far the most powerful integrated servo motor in the industry is its unique ability to control an entire machine. The SmartMotor is not just a motor; it is a complete motion control system and the result of an innovative design philosophy. The unsurpassed programming ease, networking capability, highly flexible and expandable I/O, and high power density servo performance is exactly what you should expect from the pioneer and recognized global leader of truly integrated motion control.

The simplicity and ease of use goes beyond just “compactness;” it results in overall reduced machine development time (shortening time-to-market), lower total machine cost, greater field reliability, and simplified machine design and build time, eliminating heavy procurement and support activities.

Error: Please ensure there is only one form per page. Easy Form Builder

The Class 5 SmartMotor™ is a highly programmable, fully integrated servo motor system that incorporates a motor, an encoder, an amplifier, a controller, serial communication, and IOs in one compact package. All D-style SmartMotor™ have a primary RS-232 communications port, …

Animatics – Class 5 M Style The Class 5 SmartMotor™ is a highly programmable, fully integrated servo motor system that incorporates a motor, an encoder, an amplifier, a controller, serial communication, and IOs in one compact package. They also feature …

The Animatics Class 6 D-Style SmartMotors deliver high performance and precision in a compact package. These motors integrate a motor, amplifier, controller, and multi-turn absolute encoder into a single unit. This integration provides a seamless solution for various industrial applications. With a …

Animatics – Class 6 M Style The Class 6 M-Style SmartMotor lineup includes EtherCAT® (EEC option), PROFINET® (EPN option), and EtherNet/IP™ (EIP option) versions. These motors are designed for maximum performance and connectivity. They incorporate a high-end, high-speed processor for …

A SmartMotor is an integrated servo motor, where the drive, controls, IO, program and encoder are built into the motor.

What makes the Moog Animatics SmartMotor™ by far the most powerful integrated servo motor in the industry is its unique ability to control an entire machine. The SmartMotor is not just a motor; it is a complete motion control system and the result of an innovative design philosophy. The unsurpassed programming ease, networking capability, highly flexible and expandable I/O, and high power density servo performance is exactly what you should expect from the pioneer and recognized global leader of truly integrated motion control.

The simplicity and ease of use goes beyond just “compactness;” it results in overall reduced machine development time (shortening time-to-market), lower total machine cost, greater field reliability, and simplified machine design and build time, eliminating heavy procurement and support activities.