Cone Drive’s gearsets deliver precision and durability. Trusted since 1925, their double-enveloping worm gear technology provides high torque and efficiency. These gearsets fit a wide range of applications and come in various sizes and ratios. You can customize configurations to meet specific needs. Made from high-quality materials like tin-aluminum bronze and hardened steel, these gearsets ensure long-lasting performance. Cone Drive offers zero, low, or standard backlash options, making their gearsets adaptable to diverse industrial requirements.

Form is loading

Please Wait

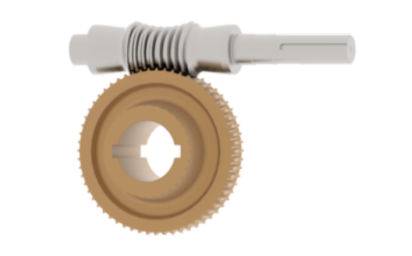

What Are Double Enveloping Gearsets?

Double enveloping gearsets enhance performance and efficiency. Unlike standard worm gears, these gearsets feature a unique design where both the worm and the gear wrap around each other. This design increases the contact area, allowing more teeth to engage at once. As a result, load distribution improves, and torque transmission becomes more efficient.

Advantages of Double Enveloping Gearsets

Higher Load Capacity

First, double enveloping gearsets handle higher loads due to the increased contact area. This reduces stress on individual teeth, enhancing durability. Additionally, the gearsets operate more smoothly and quietly, making them ideal for high-torque and precision applications like industrial machinery and robotics.

Improved Efficiency

Moreover, the larger contact area and continuous engagement of multiple teeth reduce friction and wear. This leads to higher transmission efficiency, allowing the gearsets to achieve the same power output with less energy input. Consequently, they are more energy-efficient and cost-effective in the long run.

Design Flexibility

Furthermore, these gearsets offer great flexibility in design. You can customize them to fit specific requirements, with options for various sizes, ratios, and backlash settings. This adaptability makes them suitable for a wide range of applications, from heavy-duty industrial equipment to precision instruments.

Conclusion

In summary, double enveloping gearsets provide a robust and efficient solution for high-performance applications. They combine durability, precision, and energy efficiency in a compact design.