LinMot develops, manufactures and distributes high-quality linear motors, linear rotary motors, linear modules and linear systems for use in industrial automation. You get everything for linear motion from a single source. The headquarters of NTI AG is located in Spreitenbach, near Zurich in Switzerland. As an international, innovative company with an experienced customer service, sales and support network, we are always a competent and reliable partner for the realisation of linear and rotary movements.

Featured LinMot Products

-

Developed for a demanding environment, the compact LinMot SSC linear motors are made of stainless steel EN 1.4404/AISI 316. In the construction of this motor family, the focus is on hygienic design. In order to prevent the accumulation of dirt, the motors are designed without unnecessary edges, corners, holes and screw connections.

The windings of the linear motors are completely encapsulated with epoxy resin, which protects the copper filling and also the stator package from condensation or corrosion. With this outstanding tightness, they therefore meet the IP69K protection class according to DIN EN 60529. Specially developed plastic bearings ensure simplified cleaning and a lot of time saving in wash-down applications. Furthermore, the drives are perfectly designed for “in-place” cleaning processes such as CIP and SIP.

For temperature monitoring, all linear motors are equipped with sensors that transmit the data to the drive. The data can be evaluated in the higher-level controller in such a way that the motor can be kept within a constant temperature range depending on the processing (e.g. food such as fish). As an option, LinMot offers integrated water cooling for low surface temperatures for some motor types, which leads to higher performance and at the same time reduces germ formation.

-

MagSpring products are best described by the term “magnetic spring”. The term “spring”, however, must be understood in the sense that MagSpring components exert a constant force over their entire working range, whereas a typical characteristic curve for a mechanical spring has the force increasing as a function of displacement. Generating a force that is independent of displacement makes MagSprings an excellent choice for compensating for weight forces in vertical applications.

-

The LinMot DM01 product family comprises a versatile range of linear modules designed for various industrial applications. At its core, the DM01 series features LinMot linear motors, including the PS01-23, PS01-37, and PS01-48 models. These motors offer impressive performance metrics: they can generate forces of up to 572 N, achieve stroke lengths of up to 575 mm, accelerate at rates of up to 50 m/s², and reach maximum velocities of 5 m/s. The direct mounting capability allows users to attach loads directly to the module, with built-in transverse force absorption.

-

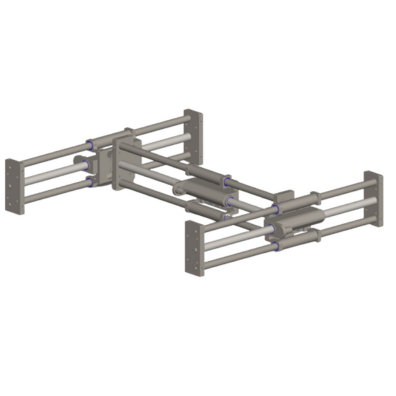

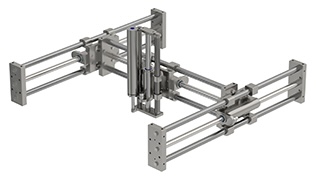

Both the F01 and E01 modules are part of the moving stator applications with linear tubular motors. Their mechanical construction is based on a special aluminum profile to which up to two high-precision profile rail modules are attached. These modules offer high guiding accuracy, allowing dynamic and precise load positioning. Additionally, they can be assembled into gantry or semi-gantry designs without requiring additional adapters. With direct mechanical compatibility across various LinMot vertical axis modules, linear rotary motors, and other products, the F01 and E01 modules provide a powerful toolbox for automation tasks

-

LinMot motors are high quality, extremely high efficiency tubular linear motors. This high efficiency means less heat generated and better position accuracy. The simple, clean tubular design makes it easy to install the motor, reducing the footprint and achieving unrivaled force density. Contrary to conventional drive solutions, LinMot solutions do not require any mechanical transmission elements – which simplifies the design, while reducing wear to almost zero and thus minimizing maintenance.

-

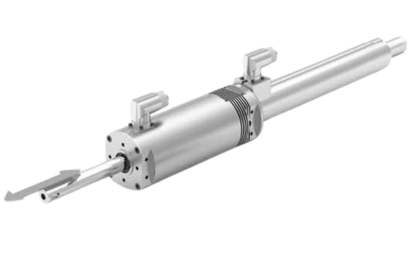

LinMot Linear Rotary Actuators seamlessly combine linear and rotary movements within a single, compact housing. These advanced actuators offer unparalleled flexibility, dynamics, and speed, making them ideal for diverse industrial applications. Moreover, with the ability to perform both linear and rotary motions independently or in sync, LinMot Linear Rotary Actuators provide precise and efficient motion control. Additionally, their innovative design, featuring programmable press forces and optional hollow shafts, ensures optimal performance and integration into various automation processes. Therefore, enhance your production capabilities with the reliability and versatility of LinMot Linear Rotary Actuators.

Home » Suppliers » LinMot » Linear Rotary

VideosAbout Linear-RotaryRequest InfoHighly Dynamic Linear and Rotary Direct Drive

LinMot’s linear-rotary motors provide precise and rapid motion control. Whether you need linear translation or rotary motion, these modules deliver outstanding performance. This high level of control ensures that your processes run smoothly and efficiently.

Independent Linear and Rotary Movements

LinMot Linear Rotary Motors allow independent linear and rotary motion, which you can synchronize if required. This versatility enables seamless integration into various automation processes, enhancing productivity and flexibility in your operations.

Programmable Press Forces and Torques

Fine-tune the force and torque output to match your specific application needs. LinMot motors offer programmable parameters for optimal performance, ensuring that you achieve the exact specifications required for your tasks.

Optional Hollow Shaft

Choose the hollow shaft option for streamlined designs and efficient integration with other components. This feature allows for more compact and efficient system designs, reducing space requirements and simplifying installation.

MagSpring Load Compensation

Enhance reliability and safety by equipping LinMot motors with MagSpring counterbalances. These virtually wear-free components ensure consistent weight compensation, improving the longevity and performance of your equipment.

Applications

LinMot Linear Rotary Actuators are suitable for a variety of applications. In the packaging industry, they provide precise and rapid movement of products, ensuring efficient packing and sorting. In assembly lines, the actuators offer the flexibility needed to handle different components and tasks. Their high-speed performance and scalability make them a valuable asset in any high-volume production environment.

Conclusion

In summary, LinMot Linear Rotary Actuators provide a fast, scalable, and versatile solution for high-volume production. Their high-speed performance, customizable work envelopes, and durable construction make them an excellent choice for various industrial applications. Whether you need to improve efficiency in packaging, assembly, or other manufacturing processes, LinMot Linear Rotary Actuators deliver reliable and efficient performance.

Form is loading

Please Wait -

Its functionality is based on the attractive force of permanent magnets. This means that no power supply is needed (electrical power, compressed air, etc.), making even safety-related applications possible. Due to the special design of the flux guiding components and the magnets, the severely non-linear relationship between force and displacement in arrangements of magnets and iron is transformed into a constant force curve.

- Purely passive, requiring neither electrical power nor compressed air

- Forces up to 60 N

- Strokes up to 350 mm

- Can be combined with H-guide

- Also suitable for dynamic motions

- Simple design

-

LinMot Robots offer a range of high-precision motion control systems, from the versatile AM01 to the robust AM14. Each model includes guides, drives, cables, and power supplies designed for smooth and accurate movement, making them ideal for various industrial applications. With components like SM01 and SM02 guides, C1250-MI drives, and S02-72/1000 power supplies, LinMot Robots ensure reliable and efficient performance.

Featured LinMot Multi-Axis Systems

-

The AM03 from LinMot is a robust motion control system designed for precision applications. It includes one EM01 or FM01 guide for the X axis, one DM01 guide for the Z axis, two C1250-MI drives, two 4-meter cables, one S02-72/1000 power supply, and additional accessories. This package ensures reliable and accurate performance, making it suitable for various industrial tasks.

Table/SpecsBill of MaterialsRequest Info

Bill of Materials

- EM01 or FM01 Guide (X axis) – 1 unit

- DM01 Guide (Z axis) – 1 unit

- C1250-MI Drives – 2 units

- 4m Cables – 2 units

- S02-72/1000 Power Supply – 1 unit

- Accessories – Various

Form is loading

Please Wait